Find the best precast concrete boundary wall machine at HENAN KELAI INDUSTRIAL CO.,LTD

Precast concrete boundary wall machine is a kind of mechanical equipment specially used for producing boundary wall panels, which is widely used in construction and infrastructure construction. The following is its detailed introduction:

一、Equipment Introduction

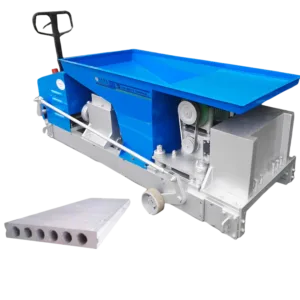

Precast concrete boundary wall machine is a kind of machinery for efficiently producing concrete wall panels, which usually includes molds, vibration molding devices, mixing systems and conveying systems. Through mechanized and automated operations, it can mass-produce concrete wall panels with stable quality.

二、Key Features

1. Concrete molding

Use molds and vibration compaction technology to mold concrete slurry into wall panels of preset sizes and shapes.

2. Section size design

By changing the mold inside the machine, concrete panels of different sizes can be pressed out, such as the size and thickness of the concrete wall panel section, which can be produced to meet your requirements.

3. Automated operation

Equipped with an intelligent control system, it can automatically complete the steps of loading, mixing, molding and demoulding to improve production efficiency.

4. Customized production

Adjust parameters such as wall panel thickness, length, connection structure, etc. according to needs.

三、Features and benefits

Equipment features

Modular design: The equipment can be flexibly expanded according to production needs.

Sturdy and durable: Made of high-strength materials, suitable for long-term continuous operation.

Energy saving and environmental protection: Low energy consumption, and waste generated during the production process can be recycled.

Advantages

1. High efficiency

Mechanized operation greatly improves production speed and is suitable for large-scale construction projects.

2. Stable quality

Using unified and standardized production, the quality of wall panels is consistent and construction errors are reduced.

3. Cost saving

Compared with traditional construction methods, it saves labor costs and material waste.

4. Convenient construction

The wall panels are easy to transport and quick to install on site, shortening the overall construction period.

四、Operation process

1. Raw material preparation

Concrete slurry is made by mixing cement, sand, gravel and additives in proportion.

2. Mold filling

The concrete slurry is injected into the mold and vibrated to eliminate bubbles.

3. Vibration molding

The vibrator is used to compact the concrete into the mold to form a dense wall panel structure.

4. Demolding and curing

After the wall panel is demoulded, it enters the curing room to ensure its strength and durability.

5. Finished product stacking

After the wall panel is completed, it is stacked, transported and sent to the construction site.

五、Market prospects

With the acceleration of urbanization and the advancement of construction technology, the market demand for precast concrete boundary wall machines is growing year by year. Its high efficiency, environmental performance and customization capabilities make it an important equipment in the field of construction.

六、Main application scenarios and advantages

1.Industrial Park Fence

Suitable for boundary wall construction of industrial plants, warehouses and logistics parks.

High efficiency and durability, large-scale fence installation can be completed quickly.

2.Agricultural and breeding sites

Provide boundary protection for farmland, orchards and breeding farms.

Provide windproof and anti-theft functions, strong structure and corrosion resistance.

3.Residential and commercial areas

Provide beautiful and practical fence solutions for residential areas and commercial centers.

A variety of textures and styles can be designed according to needs to meet aesthetic and safety requirements.

4.Highway and railway boundaries

Isolation barriers and protective walls along highways and railways.

Provide high-strength structure and excellent impact resistance.

5.Construction sites and temporary facilities

Suitable for temporary enclosures and construction safety barriers.

Reusable to reduce material waste.

6.Places with special security needs

Suitable for boundary protection in high-security areas such as military bases, airports, prisons, etc.

Enhance anti-intrusion capabilities and can be equipped with additional safety devices.

七、precast boundary wall making machine Advantages

Efficient production

Batch production and shortened construction period can be achieved through automated equipment and mold production.

Environmental protection and energy saving

Reduce the waste of resources and environmental pollution required by traditional on-site cast walls.

Cost control

The wall panels produced by the boundary wall machine are easy to transport, quick to install on site, and reduce labor costs.

Reliable quality

The prefabricated wall panels have a dense structure, excellent compression and weathering resistance, and a long service life.

Customized design

Wall panels of different sizes and styles can be provided according to customer needs to meet various project requirements.